Waste Oily Water Treatment for Engineering Workshops

Careful management of these fluids helps to extend their useful life, but ultimately they have to be disposed of.

In the UK alone engineering companies generate an estimated 400 000 tonnes/year of waste oily water and spent fluids, which represents a significant cost.

Spent metalworking fluids

Spent metalworking fluids contain a layer of free/separated oil (5 – 10%), a soluble phase including emulsified oil (80 – 90%) and a small amount of solid material (<0.5%). A mixture of toxic organic compounds, e.g. biocides and surfactants, is dissolved in the water phase.

These compounds are unsuitable for discharge to sewer without treatment. Established processes, such as oleophilic mops, can remove the free/separated oil, while emulsified oil can be separated into organic and aqueous phases, e.g. by ultrafiltration. The water soluble components, however, remain unaffected by these processes and may find their way into the environment and cause harm.

Oil recovery

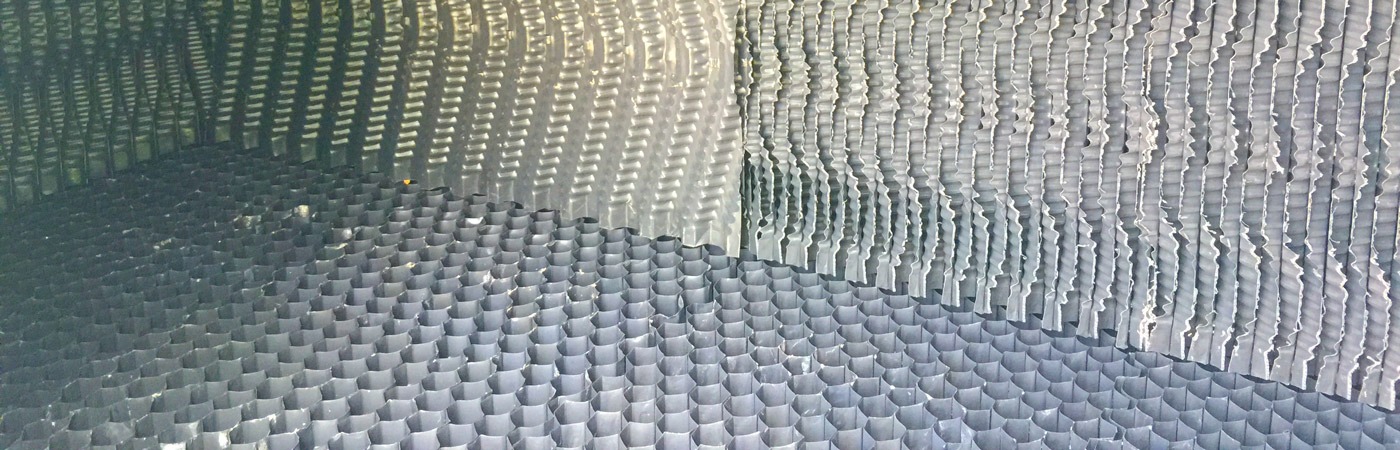

Spent metalworking fluids contain a mixture of free and emulsified oils together with a cocktail of toxic, water-soluble organic compounds. Free and emulsified oils can be recovered using existing treatment techniques, but the water-soluble components are unaffected and remain in the water phase. A prototype system to remove soluble organic compounds from oily wastewater was developed and tested at a site belonging to one of the project partners. The system uses a novel synthetic carbon adsorbent and low-temperature, in-situ carbon regeneration.

Trials showed that the prototype system significantly reduced the chemical oxygen demand (COD) of wastewater that had been pretreated to remove free and emulsified oils. The polished water is potentially suitable for reuse on-site.

The benefits of this novel treatment system include:

- Up to 90% reduction in wastewater COD.

- Reduced waste disposal charges.

- Significant reduction in water consumption.

- Potential application to oily wastewaters from other industries… request a copy of the full document >>

Crown copyright material is reproduced with the permission of the Controller of HMSO and the Queen’s Printer for Scotland