Ultrasound Cleaning of Ceramic Filters to Aid Water Treatment

Although the research is still in its early stages, they claim the technology may one day allow water treatment plants to purify water with ceramic membrane filters instead of traditional water treatment chemicals.

Harold Walker, assistant professor of civil and environmental engineering and geodetic science at Ohio State University said “If water treatment plants could clean water with membrane filters, they could minimize the cost, safety and disposal issues associated with the use of harsh chemicals,”

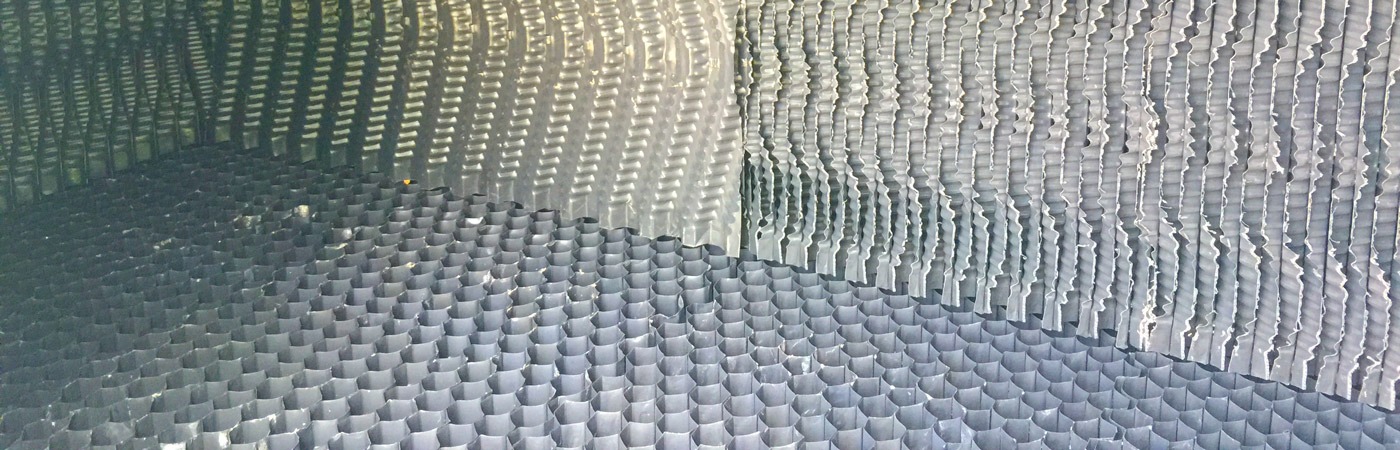

Researchers are currently studying ceramic membrane filters, honeycomb networks of micro-channels separated by thin ceramic membranes. As water passes through the micro-channels, the ceramic membranes act to filter contaminants including clay, iron oxide, bacteria and viruses. However, over time these membranes become clogged and require cleaning.

Ultrasound and bubbles

Walker took note of recent research involving ultrasound and bubbles. The idea, most recently reported by scientists at Oak Ridge National Laboratory and their colleagues, is that sound waves can form and collapse bubbles inside a liquid, releasing heat and energy.

To test whether collapsing bubbles could clean a ceramic filter, the engineers submerged a filter in water that contained latex and silica particles. They used particles in a range of sizes to mimic the contaminants found in water treatment.

They used an ultrasonic probe to vibrate the water at 20 Kilohertz, a low frequency that is easily obtainable with typical ultrasound equipment. For example, the fetal ultrasound tests that women undergo during pregnancy employ much higher frequencies, in the order of 10 Megahertz. But that doesn’t mean a 20 Kilohertz probe is less powerful, Linda Weavers, also assistant professor of civil and environmental engineering and geodetic science at Ohio State University, explained.

“Frequency has nothing to do with power. Think of it as bass sounds versus soprano sounds. Both can be louder or softer. Whether a sound is bass or soprano depends on frequency, whereas loudness and softness depend on power,” she said.

The 20 Kilohertz vibrations caused bubbles to form and collapse, and kept the ceramic filter clean.

“The bubbles seemed to scour the surface of the filter,” Weavers said. “Where the bubbles collapsed, tiny water jets formed and flushed away the contaminants.”

Though the engineers are still not certain exactly how the process works, Weavers suspects that the jets sprang from vibrational nodes, locations along the surface of the filter where ultrasonic waves merge together and magnify each other.

With ultrasound as a cleaning method, water treatment plants wouldn’t have to remove filters from use to clean them, Walker said. Loosened contaminants would wash away in an exhaust flow separate from the clean water.

“If you left the ultrasound running, you could clean a filter while it was still in use, and keep it from ever getting clogged in the first place,” Weavers added.

If all goes well, Walker said, the technology may be ready for full-scale testing in a water treatment plant within the next few years.

Extracted from an article originally written by Pam Frost Gorder.

——

Accepta Ltd is a manufacturer and supplier of water treatment chemicals which are produced in the UK and shipped internationally.