Paper & Board Mills – Cost Effective Effluent Treatment

This good practice guide is intended to help mills optimise the performance of their effluent treatment plant by evaluating their existing processes and then implementing measures recognised as good practice within the industry. The guide describes the main control parameters for each process and explains how to address common effluent treatment issues.

Effluent treatment plant

Before reviewing the operation of their effluent treatment plant, mills are urged to take action to minimise the amount and strength of the effluent produced by the mill. Producing less effluent in the first place will reduce the demands made on the effluent treatment plant and thus save both money and effort. Effective balancing to even out the flow and load on the effluent treatment plant is also important for cost-effective operation.

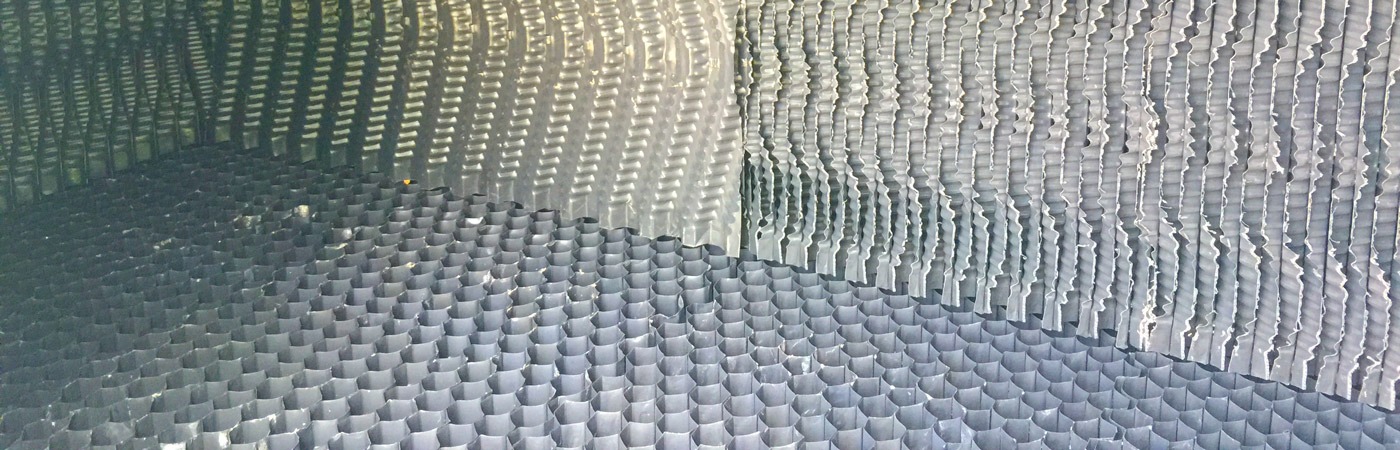

- Primary treatment to remove fibre and other suspended solids from the process;

- Secondary biological treatment (aerobic or anaerobic) to remove soluble organic pollutants;

- Tertiary treatment, ie effluent polishing, to produce water of a quality suitable for recycling to mill processes and/or remove residual pollutants;

- Sludge dewatering to reduce sludge treatment and disposal costs.

To minimise operating costs while retaining acceptable performance, it is essential to understand the different processes and to monitor key control parameters. The guide pays particular attention to the activated sludge process, with an overview of the microbiology of this process and suggestions on how to optimise the process in terms of the food: mass ratio, sludge age and dissolved oxygen content. Ways of preventing and tackling common operational problems, e.g. bulking activated sludge and foaming, are described.

Five industry examples illustrate the improvements that can be made by implementing the measures described in this guide.

Optimising the operation of the effluent treatment plant will reduce the mill’s operating costs and make it easier for the mill to comply with its discharge consent conditions. Mills discharging to sewer will also reduce their trade effluent charges.

Contents of the guide include

- Introduction

- Primary treatment

- Secondary biological treatment

- Tertiary treatment

- Sludge treatment and disposal

- Industry Examples

- Action Plan… request a copy of the full document >>

Extracted from “Cost Effective Effluent Treatment in Paper and Board Mills” © Crown copyright