Reverse Osmosis (RO) Membrane Scale Inhibitors

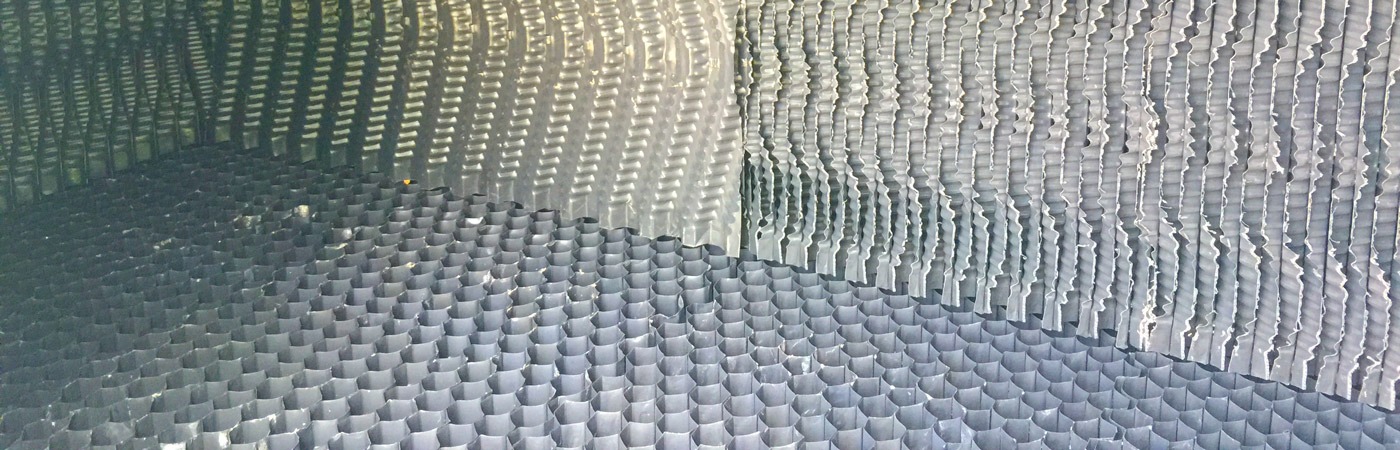

Reverse osmosis membranes

Reverse osmosis plant has at their heart a membrane that if damaged reduces output, increases costs and gives poor water quality so it is important to keep it clean and operating efficiently.

Most reverse osmosis membranes are formed from hollow fibre or thin film composite sheets with the membrane allowing passage of pure water and rejecting the dissolved solids contained in the water.

Calcium carbonate and calcium sulphate

As water passes along the membrane surface the solids concentration increases and some sparingly soluble salts start to exceed their solubility and precipitate. When precipitated onto the membrane surface this causes fouling that may reduce output and increase product water conductivity. The worst of these solids being calcium carbonate and calcium sulphate and so the prevention of their precipitation is vital if the membrane is to function efficiently.

The traditional way to prevent this was to “de-alkalise” the water using sulphuric acid to prevent calcium carbonate precipitation. However, the acid is hazardous increases the sulphates and increases the corrosivity of the water on both sides of the membrane. Reducing the recovery rate of the reverse osmosis plant eliminated calcium sulphate but this reduces the efficiency of the plant and hence increases costs.

RO membrane antiscalants

Effective membrane antiscalants should be:

- Safe to handle and safe to use.

- Good scale inhibitors.

- Membrane compatible.

- Effective across a wide pH range.

- Compatible with other products.

- Cost effective.

Residual iron levels

It is also normal operating practice to keep residual iron levels in the feed water as low as possible, normally below a maximum set by membrane manufacturers.

Precipitated iron is a membrane foulant and adversely affects the performance of many antiscalants.

With this in mind, it is important to design chemical and maintenance programs that are capable of meeting all of the above to ensure problem free running together with low operating costs.

Should you need assistance in any of these areas please contact Accepta who can help provide the requirements needed to assist with such plant, maintain their efficiency and thus reduce costs and improve plant life expectancy.

————–

Accepta Ltd is a manufacturer and supplier of Reverse Osmosis water treatment chemicals which are produced in the UK and shipped internationally.