Water Efficiency – Textile & Leather Industries

All water used must eventually be discharged as effluent, incurring a charge from the water company based on its volume, chemical oxygen demand (COD) and total suspended solids (TSS). This is especially so in the textile and leather industries due to the large amounts of water used.

Water consumption

Before introducing any measures to save water, it is essential to know the current level of water use and to have the means of measuring future consumption.

It is important to identify where water currently enters and leaves the building, and also how it is used. This will help you to detect leaks and identify areas with the potential for the greatest savings. Doing this should also help to highlight the true costs associated with water use. These include not only the purchase and disposal prices, but also the costs of pumping, treatment, loss of valuable materials in the effluent, and the costs of maintaining the distribution network.

Water saving measures

Having identified where potential water savings can be made, the next step is to introduce appropriate water-saving measures. This may involve installing devices such as sensors and cutoff controls for pumps, or counter-current rinse systems. It will involve a range of good ‘housekeeping’ practices and training to raise staff awareness.

Few employees will be aware that one washroom tap left trickling, instead of being properly turned off, could cost £42 per year in water and effluent charges. A 25 mm hose, left running at 66 litres per minute, wastes 4000 litres per hour and could add over £45,000 to the annual water services bill.

Water reuse

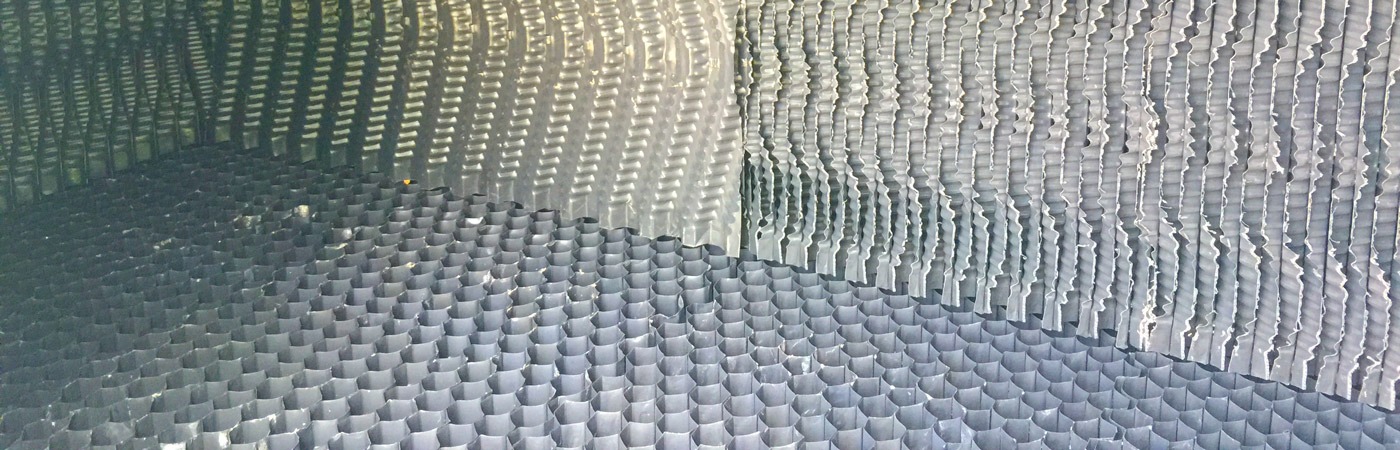

An important area for textile and leather producers to consider is the re-use of water, for example, in cleaning or cooling operations. It may be possible to introduce counter-current rinsing to the process. This consists of rinsing the product in a series of tanks or stages, each using progressively cleaner water. The rinse water is reused by moving it progressively from the last rinse tank towards the first.

Wash water may also be suitable for reuse elsewhere on site, such as for floor washing, rinsing containers or making up raw materials slurries. If used water is treated to remove impurities or recover lost raw materials, it may open up other possibilities for re-using it.

Water and wastewater costs

Cutting water and wastewater costs need to be approached systematically and should:

- Involve all members of staff

- Develop a clear, understandable plan

- Establish the true costs of water and wastewater

- Identify all water inputs and outputs

- Allocate annual water consumption between major users

- Implement all feasible water-saving options