Common Causes of Industrial Plant Failure

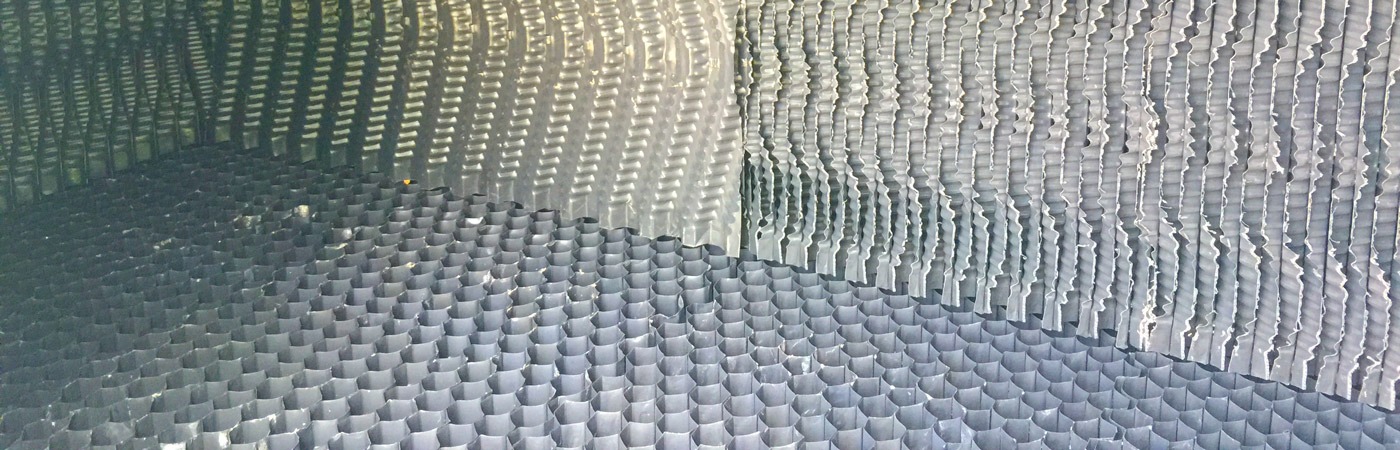

Corrosion

Corrosion is caused by electro-chemical processes in which a metal reacts with its environment to form an oxide or compound by the formation of cells comprising an anode (the deteriorating metal), a cathode (adjacent metal) and a conducting solution (acid/salts). It can occur both internally and externally to pipelines, vessels, plant, machinery, structures and supports. (See our list of corrosion Inhibitors)

Materials selection

The materials selection philosophy aspect of the design phase of all plant and structures should take into account the anticipated conditions (pressure, temperature and atmosphere) and the contents of the system in order to either minimise corrosion or to make adequate allowances for it in the form of additional material thicknesses.

Some further aspects of the use of different materials for various applications are discussed in Materials Commonly Used in Process Plant.

The initial corrosion on some metals creates an impervious coating which prevents further corrosion taking place.

Corrosion can be exacerbated by utilising different materials which then set up an electrochemical cell which in turn causes wastage of the anode.

Contents of the guide

Other causes of industrial plant failure covered in the guide include:

- Corrosion

- Erosion

- External Loading

- Impact

- Pressure

- Temperature

- Vibration

- Wrong Equipment

- Defective Equipment

- Human Error… request a copy of the full document >>