Steam Boiler Corrosion Control

Preventing Boiler Corrosion is done through the removal of oxygen and maintaining appropriate alkalinity levels in the boiler water to prevent acid attack.

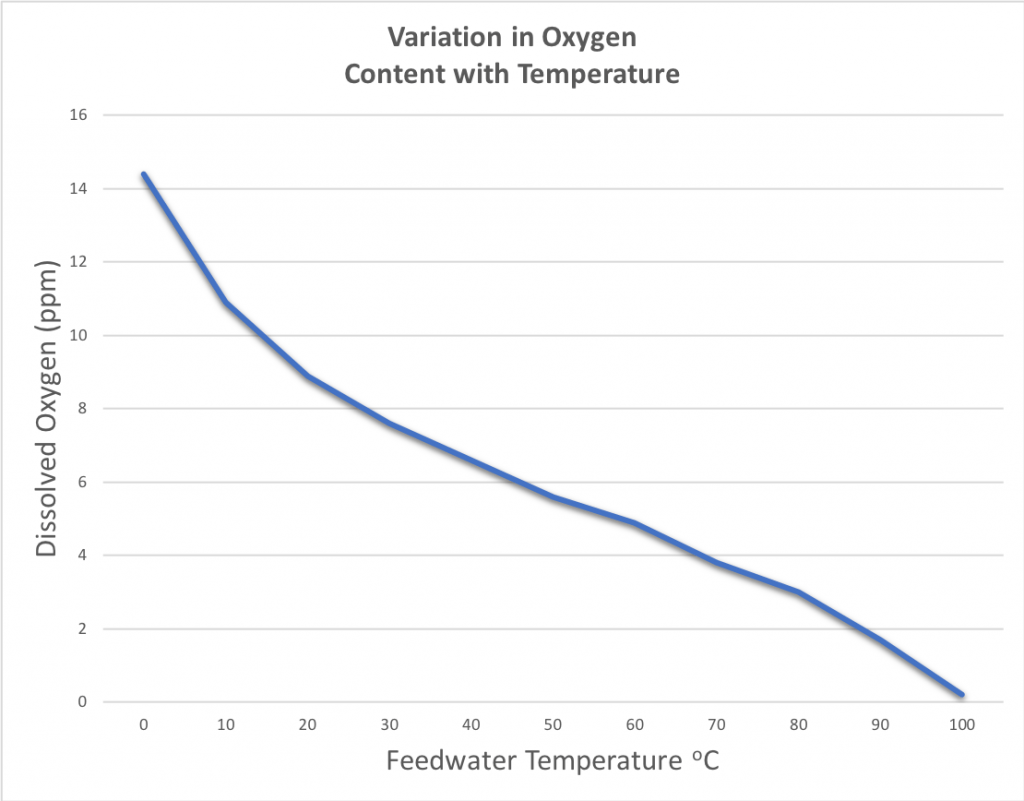

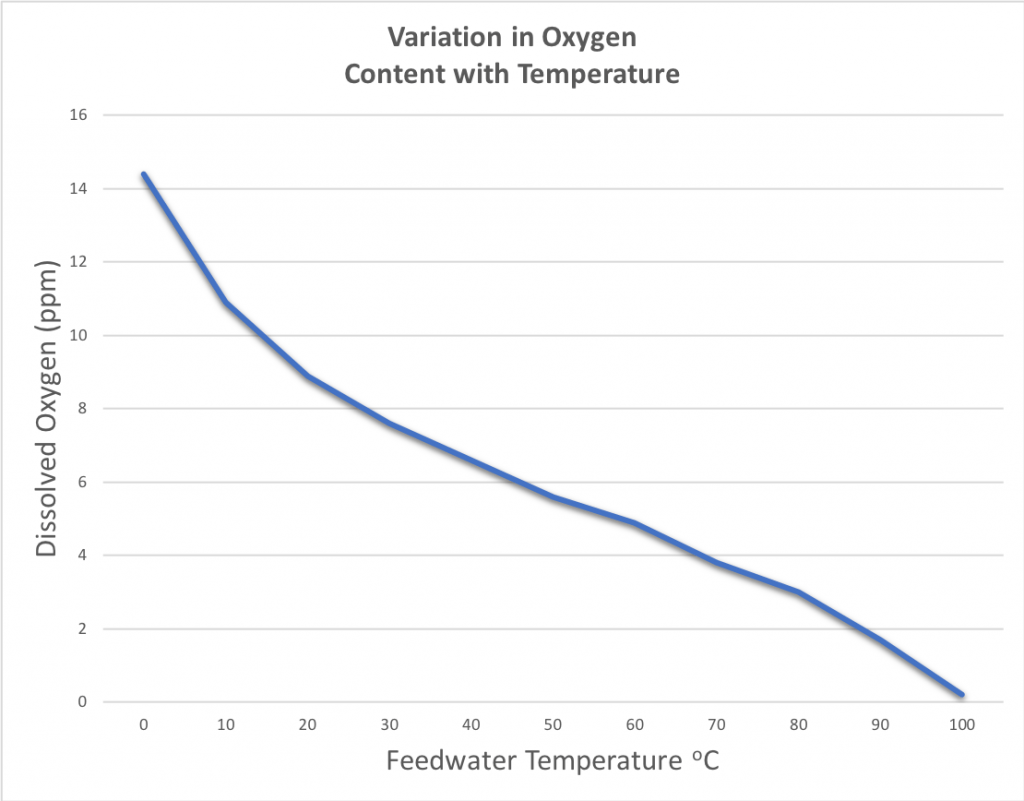

As shown in the chart oxygen levels are tied to the Hotwell feed water temperature with nearly all oxygen gone by the time the water reaches 100oC. For this reason, we recommend keeping the temperature above 80oC and incorporating an Oxygen Scavenger such as Accepta’s high-quality Sulphite or Tannin blends featured above. This will help maintain excellent boiler corrosion control and limit the potential for oxidation.

The other risk in an industrial boiler is acid attack which is caused by insufficient levels of alkalinity. Alkalinity naturally builds in a boiler as cycles of concentration increase and in many cases, a bespoke treatment plan will include additional alkalinity builders with a maximum recommended limit of 1200ppm (M Alkalinity) in a Shell boiler running at TDS of 3000ppm. Accepta Alkalinity Builders are available as separate chemicals or as part of our Multi-functional Boiler Treatment detailed below.

Multifunctional Products

You may also want to look at our range of Multi-functional Products which combine the oxygen scavenger with a polymer sludge conditioner & alkalinity builder to create a single easy to use liquid to simplify dosing and control.

Click here to see the range …