Dry Polymers

Accepta's advanced technology dry polymers offer superior performance in a dry powder form. Also supplying super absorbent polymer granules.

See ProductsAccepta’s advanced polymer products include polymer blocks, and dry/powder and emulsion/liquid polymers.

Accepta polymers (PAM) have been developed to suit a wide variety of wastewater treatment and effluent treatment applications and includes structured polymers, co-polymers; and low, medium, high and very high molecular weight cationic and anionic polymers in both liquid/emulsion and dry/powder forms.

Polyelectrolytes (most often referred to as Polymers) are long chain molecules that can produce highly charge ions when dissolved in water. Anionic Polymers produce a negative charge ion where as Cationic Polymers produce a positive charge ions when dissolved in water.

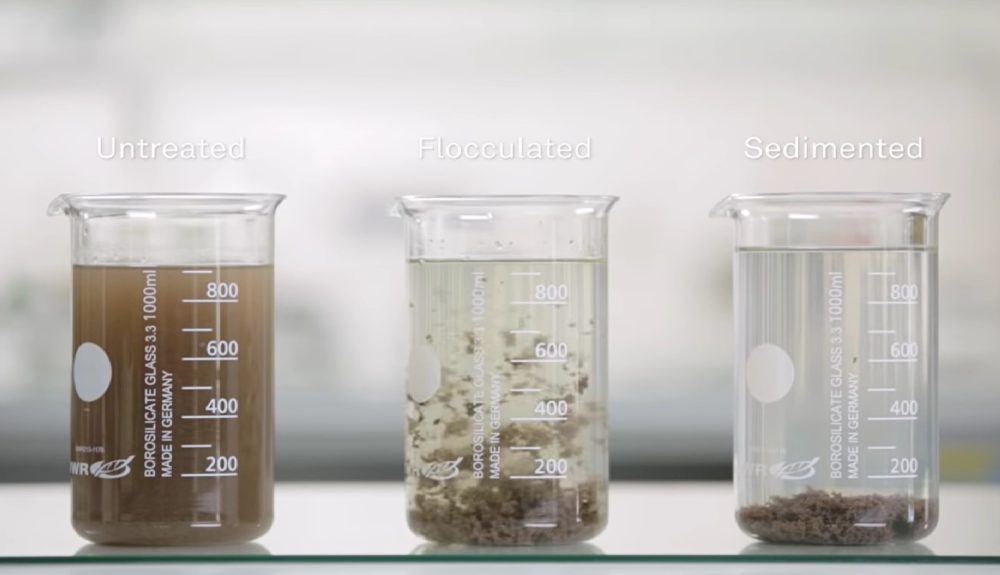

Most particulate matter/non-settling matter in surface water carry a negative charge, the addition of a positively charged coagulant such as Alum will neutralise the particles allowing them to floc together. The secondary process would be to add a Polymer (typically Cationic) to help keep the floc together by bridging the microfloc to form macrofloc & allow for sedimentation. Dosage rate for the polymer would be significantly lower than the metal salts added initially.

Coagulants and flocculants are two types of chemicals that are often used together in wastewater treatment to improve the efficiency of the treatment process. Here’s how they work together:

Coagulants:

Coagulants are chemicals that are added to wastewater to destabilize suspended particles and create small aggregates or “flocs”. Coagulants work by neutralizing the charge of the particles, causing them to come together and form small clumps that can be more easily removed from the water. Common coagulants used in wastewater treatment include aluminum and iron salts, such as aluminum sulphate (alum), Poly Aluminium Chloride (PAC) and ferric chloride .

Flocculants:

Flocculants are chemicals that are added to wastewater after coagulation to promote the formation of larger, more stable flocs that can be more easily removed from the water. Flocculants work by adsorbing onto the surface of the particles and creating bridges between them, causing them to come together and form larger flocs. Common flocculants used in wastewater treatment include polyacrylamide and other polymers.

Together, coagulants and flocculants work to improve the efficiency of wastewater treatment by creating larger flocs that are easier to remove from the water. Coagulants destabilize the particles and create the initial flocs, while flocculants promote the growth and stability of the flocs. By working together, coagulants and flocculants can improve the overall quality of the treated wastewater and reduce the amount of solids , associated chemical oxygen demand and other contaminants that are discharged into the environment.

Flocculants are chemicals used to promote the aggregation of suspended particles in water to form larger flocs. The performance of flocculants can vary depending on their molecular weight and the characteristics of the trade effluent water.

High molecular weight flocculants typically have better performance than low molecular weight flocculants in terms of their ability to agglomerate suspended particles and create larger flocs. This is because high molecular weight flocculants have more complex, longer molecular chains that can provide a greater surface area for particle adsorption, leading to larger and more stable flocs.

Additionally, high molecular weight flocculants typically have a slower dissolution rate, allowing them to remain in the water for a longer time, providing better opportunities for particle contact and aggregation.

However, high molecular weight flocculants can be more expensive than low molecular weight flocculants due to the higher cost of production and purification, and can be more difficult to handle and apply due to their higher viscosity.

Ultimately, the choice between high and low molecular weight flocculants will depend on the specific application, the type of coagulants used and the desired performance, as well as cost considerations.

Cationic and anionic charged flocculants are used in different applications depending on their charge and properties. Here are some examples:

Cationic flocculants:

Cationic flocculants have a positive charge and are commonly used in water and wastewater treatment, especially for treating industrial wastewater. Cationic flocculants are effective in removing suspended solids, colour, and organic matter from water. They work by neutralizing the negatively charged particles in the water, causing them to agglomerate and form larger particles. Cationic flocculants are also used in sludge dewatering, where they can improve the efficiency of the dewatering process.

Anionic flocculants:

Anionic flocculants have a negative charge and are commonly used in the treatment of municipal and industrial wastewater. They are effective in removing colloidal and suspended particles, as well as heavy metals and organic matter. Anionic flocculants work by adsorbing onto the surface of particles, causing them to repel each other and form larger flocs. Anionic flocculants can also be used in the paper and pulp industry, as well as in mining and oil and gas production, where they are used to improve solids settling and enhance water clarification.

The choice of cationic or anionic flocculants will depend on the specific application and the properties of the wastewater or other liquid being treated. It is important to select the appropriate flocculant for each application to achieve the best possible treatment results.

Matching the correct coagulant and flocculant for your application requires consideration of several factors, including the nature of the wastewater, the type and concentration of pollutants, and the desired quality of the treated water.

Here are some general guidelines for selecting coagulants and flocculants:

It is important to note that there is no one-size-fits-all solution when it comes to wastewater treatment. You should consult with a professional to determine the best coagulant and flocculant for your specific application.

If you have any more questions or are looking for technical assistance please fill out the contact form below.

Accepta's advanced technology dry polymers offer superior performance in a dry powder form. Also supplying super absorbent polymer granules.

See ProductsAccepta's advanced technology emulsion polymers offer superior performance with the convenience of a liquid.

See ProductsPlease complete this form and we will be in touch