Selecting your Boiler Scale Inhibitor

Accepta provides two kinds of scale inhibitor – Polymer only and Polymer Phosphate, the latter of which is the required option under the following conditions:

- Phosphate must be used in boilers operating at pressures above 19 bar (150 psi)

- The ‘natural’ Alkalinity of the make-up after sulphite addition is less than 20% of the TDS or make-up is dealkalised

- Or when the make-up water is not efficiently softened

Polymer Phosphate treatment regimes precipitate magnesium & calcium hardness salts from boiler make-up water in the form of hydroxyapatite and serpentine. These compounds form sludge, which, when properly conditioned with polymers, is removed from the boiler during blowdown. When a significant excess of soluble orthophosphate and free hydroxide (caustic) alkalinity is maintained in the boiler water, calcium carbonate formation can be virtually eliminated. Polymeric dispersants or sludge conditioners are added with the phosphate to condition the sludge for improved removal from the boiler. See Accepta 2112 & 2347 for high-quality boiler phosphate treatment.

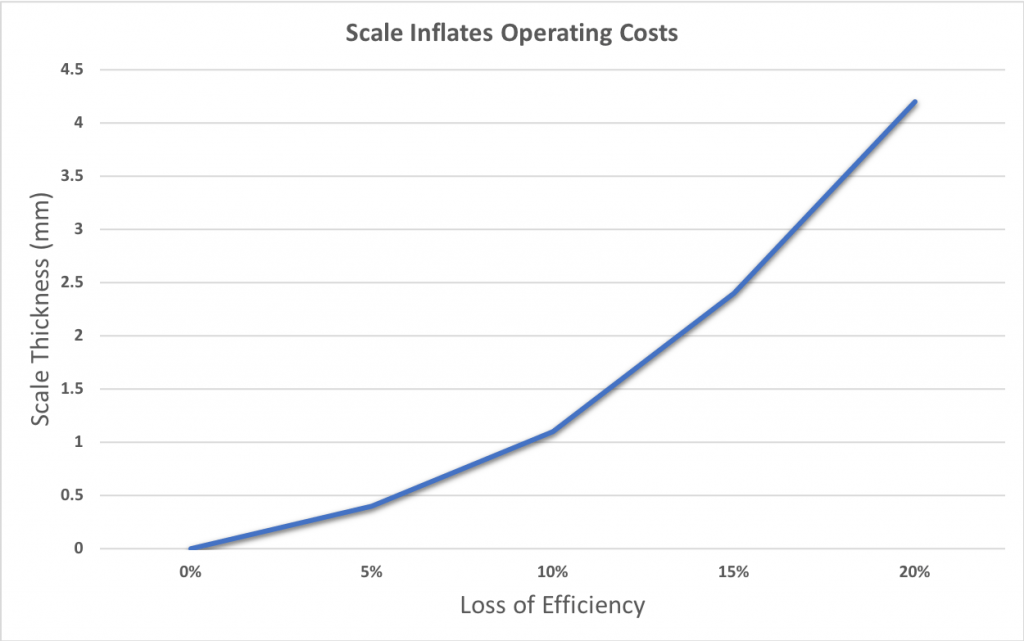

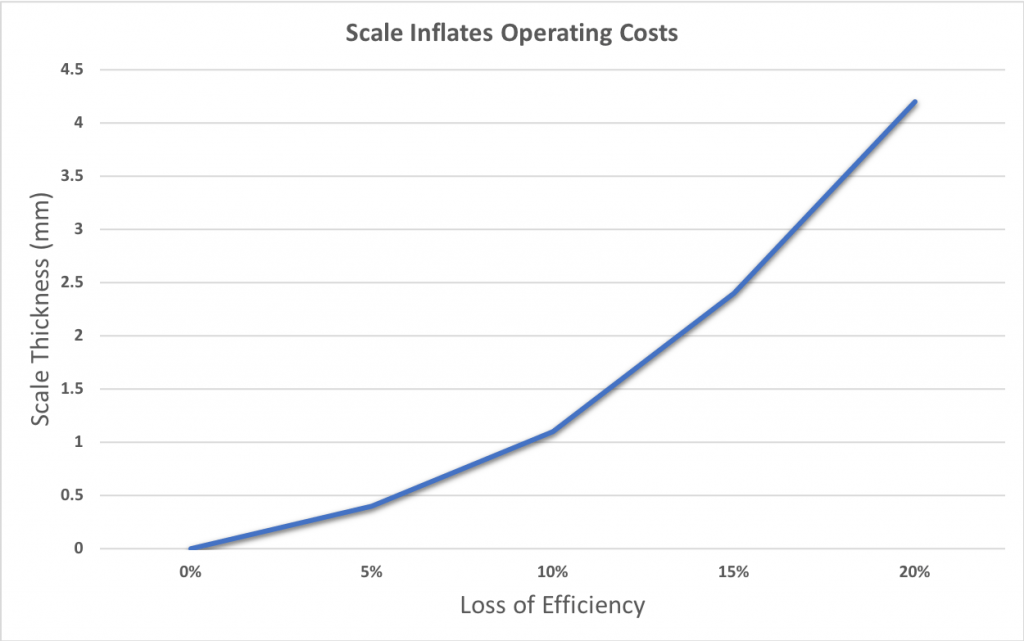

Correct Boiler Treatment is immensely important as poor treatment regimes can lead to significant increases in operating costs with scale acting as insulation on the boiler tubes reducing the amount of energy transferred from fuel burn to boiler water temperature. With 80% or more of boiler house costs coming from fuel that can mean a lot of money being wasted out of the smokestack.

Correct Boiler Treatment is immensely important as poor treatment regimes can lead to significant increases in operating costs with scale acting as insulation on the boiler tubes reducing the amount of energy transferred from fuel burn to boiler water temperature. With 80% or more of boiler house costs coming from fuel that can mean a lot of money being wasted out of the smokestack.

Dosed into the feed water tank Accepta’s Polymer Phosphate scale treatment chemicals are ideal additions to your boiler treatment program and can be combined with Oxygen Scavenger Corrosion Inhibitors & Multi-functional Boiler Chemicals such as Accepta’s range of blended Tannins and Sulphite treatments.

A Polymer Phosphate treatment helps to keep hardness in suspension by converting it to a sludge which can be removed by blowdown. Your makeup water should be softened down to a level below 1ppm of hardness with your Water Softener tested weekly. If you require a Water Softener speak to Accepta today.

Silicate Scale Prevention

Silicate scales can easily be formed in boilers at moderate temperatures and pressures. They are particularly likely where the feed water silica content is a high proportion of the dissolved solids and the feed alkalinity is low.

Due to their clingy nature and low thermal conductivity, silicate scales can be particularly damaging and should be prevented by adopting all of the following measures:

- Adequate pre-treatment such as lime softening, ion exchange and reverse osmosis.

- Maintain adequate phosphate or carbonate reserve

- Maintenance of a silica caustic alkalinity ratio of 0.4 : 1

- Limitation of the boiler water silica level down to 0.02ppm

Correct Boiler Treatment is immensely important as poor treatment regimes can lead to significant increases in operating costs with scale acting as insulation on the boiler tubes reducing the amount of energy transferred from fuel burn to boiler water temperature. With 80% or more of boiler house costs coming from fuel that can mean a lot of money being wasted out of the smokestack.

Correct Boiler Treatment is immensely important as poor treatment regimes can lead to significant increases in operating costs with scale acting as insulation on the boiler tubes reducing the amount of energy transferred from fuel burn to boiler water temperature. With 80% or more of boiler house costs coming from fuel that can mean a lot of money being wasted out of the smokestack.